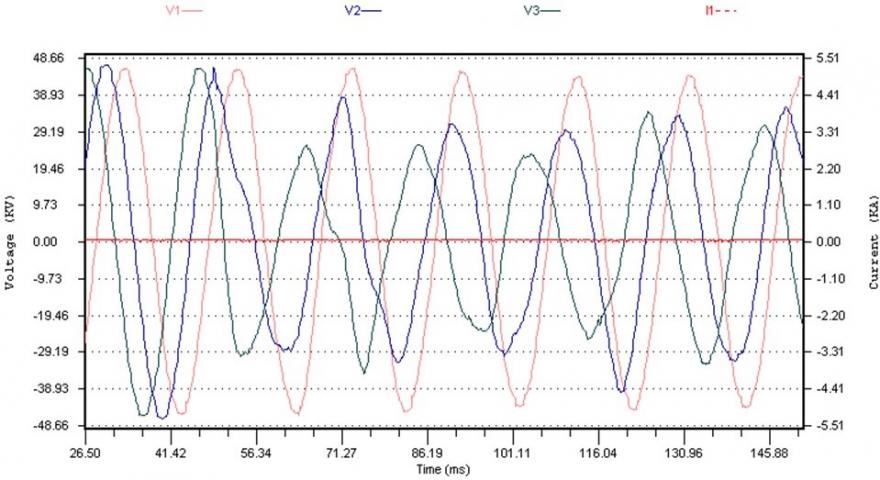

Power system at transient stability limits: A 220kV double circuit parallel grid power transmission line-1 and line-2 were supplying to an integrated steel plant with a maximum demand of 500MW. Each 220kv grid incomer PCC was connected to 2sets of 155mva, 220kv/33kv grid transformers. Power Quality measurements were carried-out at the common 33kv secondary bus, wherein all four grid transformers were connected in parallel. High wind swayed a tree over line-1, about 5km upstream of the steel plant. But the incident had failed to trip the faulty 220kv power line-1 instantly, on a direct distance protection as being under reach at the fault zone, and that caused a massive voltage sag issue. Finally, the second level of protection relays, the backup protection, cleared and tripped the faulty 220kv line-1. But it took 24-cycles time to do so.

Line-2 was healthy, but being in parallel with the faulty line-1, was also facing the same momentary voltage sag problem. It recovered to normalcy after 24-cycles, after backup protection tripped and cleared the faulty line-1.

The voltage sag effect at 5km away, at 33kV downstream of the steel plant, which then had in operation one Siemens Germany supplied, 190mvar Static VAR Compensation (SVC) System, comprising of a 190mvar Thyristor Controlled Reactor (TCR), and a combination of 180mvar Net Capacitive harmonic filters distributed among 50mvar in 2nd, 30mvar in 3rd, 30mvar in 4th, and 70mvar in 5th harmonic filters.

The incident gave rare opportunity for online efficacy testing of a SVC system, BY INJECTING A LONG-TERM VOLTAGE SAG AT ITS BUS TRANSFORMER'S UPSTREAM. Eventually the SVC itself could not hold and tripped, as the swaying tree bucked the grid voltage down for 480milli-seconds before recovering, as shown in the recorded 3phase long-term voltage sag waveform, covering the entire duration of the fault. It also tripped the 150mva, 33kv/ 1120v AC EAF transformer, Hot Rolled Mills (HRM), and all major machineries at the steel plant.